Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Products

Brand: KST

Packaging: bubble bags, carton, wooden boxes

Transportation: Ocean,Land,Air

Place of Origin: NINGBO CHINA

Certificate: ISO9001:2015;TS16949

HS Code: 8481901000

Port: NINGBO

Payment Type: L/C,T/T,D/P,Paypal

Incoterm: FOB,CFR,CIF,EXW

Cold Hot Forging

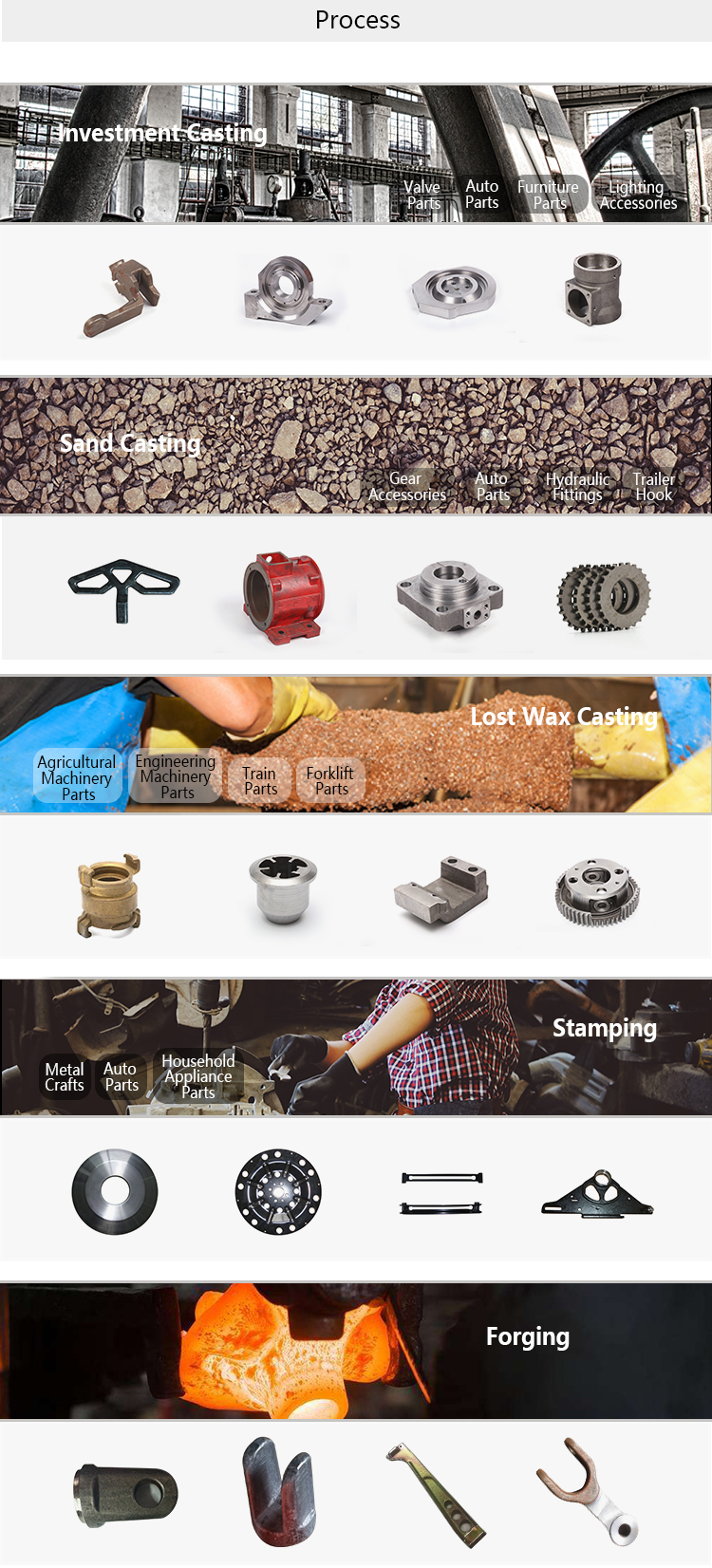

We are specializing in:

1. Sand Casting (Grey iron, ductile iron, aluminum,etc.)

2. Investment Casting (carbon steel, stainless steel, alloy steel,etc.)

3. Die Casting(aluminum, zinc, etc.)

4. Machining(CNC Center, CNC Lathe , Lathe , Drilling Machine, Milling Machine, Pressing Machine, etc.)

Certificate: ISO9001:2015, TS16949

| Item Name | OEM customized rolled ring strainless steel casting die titanium forging part with investment casting | ||

| General Products | Metal Parts Solution for Vehicle, Agriculturemachine, Construction Machine, transportation equipment, Valve and Pump system, Agriculture machine metal Parts, engine bracket, truck chassis bracket, gear box , gear housing , gear cover, shaft, spline shaft , pulley, flange, connection pipe, pipe, hydraulic valve , valve housing ,Fitting , flange, wheel, fly wheel, oil pump housing, starter housing, coolant pump housing, transmission shaft , transmission gear, sprocket, chains etc. | ||

| Process | Forging , Press | ||

| Blanks Tolerance | +/-0.3~+/-2 mm | ||

| Applicable Material | Carbon steel, Low Carbon steel, middle carbon steel, 40Cr, 20CrMnTi, 20CrNiMo etc. | ||

| Forging Blank Size | 142 mm- 300mm or according to customer requirement | ||

| Blanks Weight | Range from 0.1kg-1000kg | ||

| Applicable Machining Process | CNC MACHINING/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/ Broaching/Reaming etc. | ||

| Machining Tolerance | From 0.005mm-0.01mm-0.1mm | ||

| Machined Surface Quality | Ra 0.8-Ra3.2 according to customer requirement | ||

| Applicable Heat Treatment | Normalization , quenching and tempering, Case Hardening, Nitriding, Carbon Nitriding, Induction Quenching | ||

| Applicable Finish Surface Treatment | Shot/sand blast, polishing, Surface passivation, Primer Painting , Powder coating, ED- Coating, Chromate Plating, zinc-plate, Dacromat coating, Finish Painting, | ||

| MOQ of mass production | 100 pcs | ||

| Lead Time | 25~45 days for steel forging metal parts | ||

Product Categories : Investment Casting > Agricultural Machinery Parts

Home > Products > Investment Casting > Agricultural Machinery Parts > rolled ring casting die titanium forging part

Send Inquiry

Ms. Wendy

Tel:86-0574-88067759

Fax:

Mobile Phone:+8613777124360

Email:sales@cnsandcasting.com

Address:shiqiao Village,Yunlong Town,Yinzhou District, Ningbo, Zhejiang

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.